Painting Flush Mount Speaker Lids

Print Instructions

|

Our Speaker Lids with Flush LEDs are one of our favorite parts. Our custom speaker lids are a great way to add high-quality audio to your bike and also increase visibility. Our Speaker Lids with Flush LEDs are finished in final primer which is ready to go directly to paint. The instructions below are a step-by-step guide through this process. |

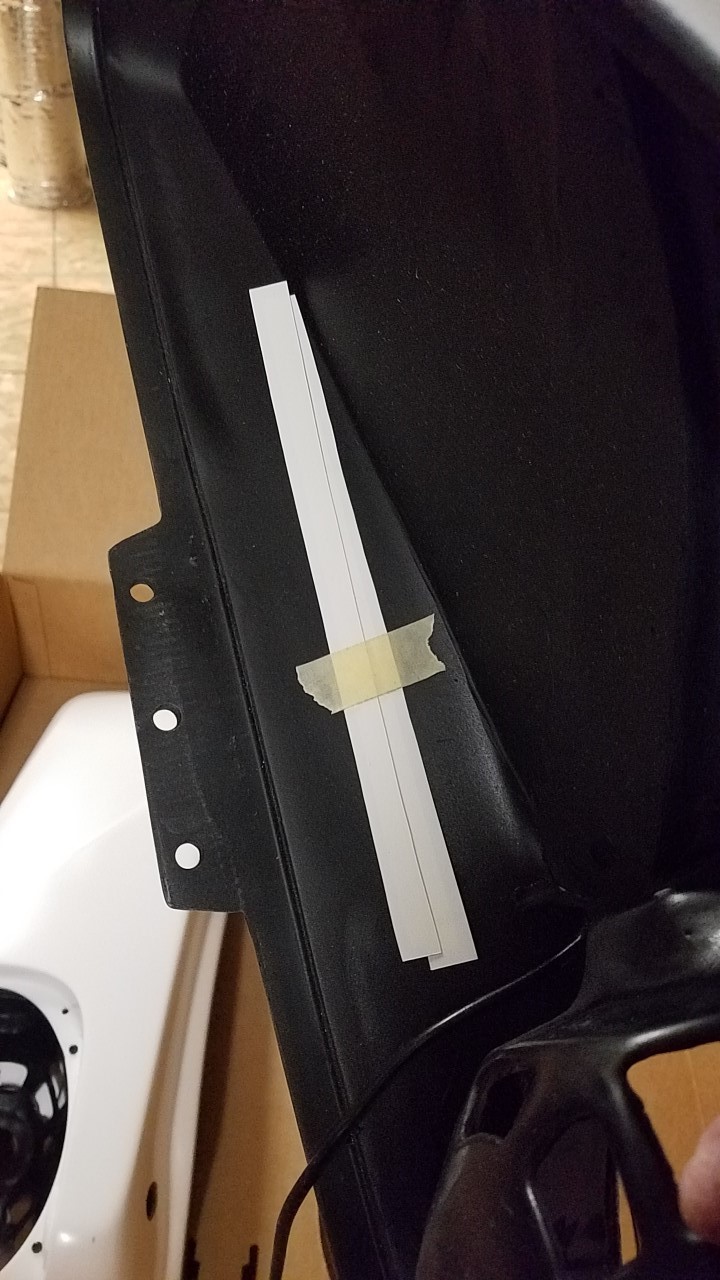

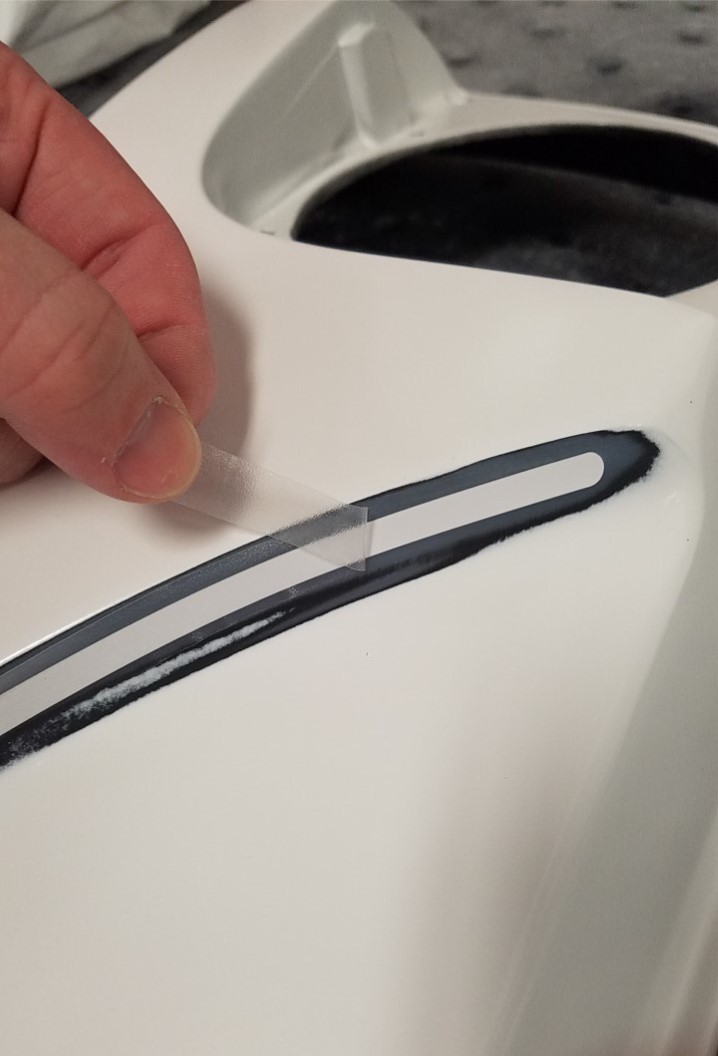

Once positioned, press firmly to adhere the stencil to the lid.

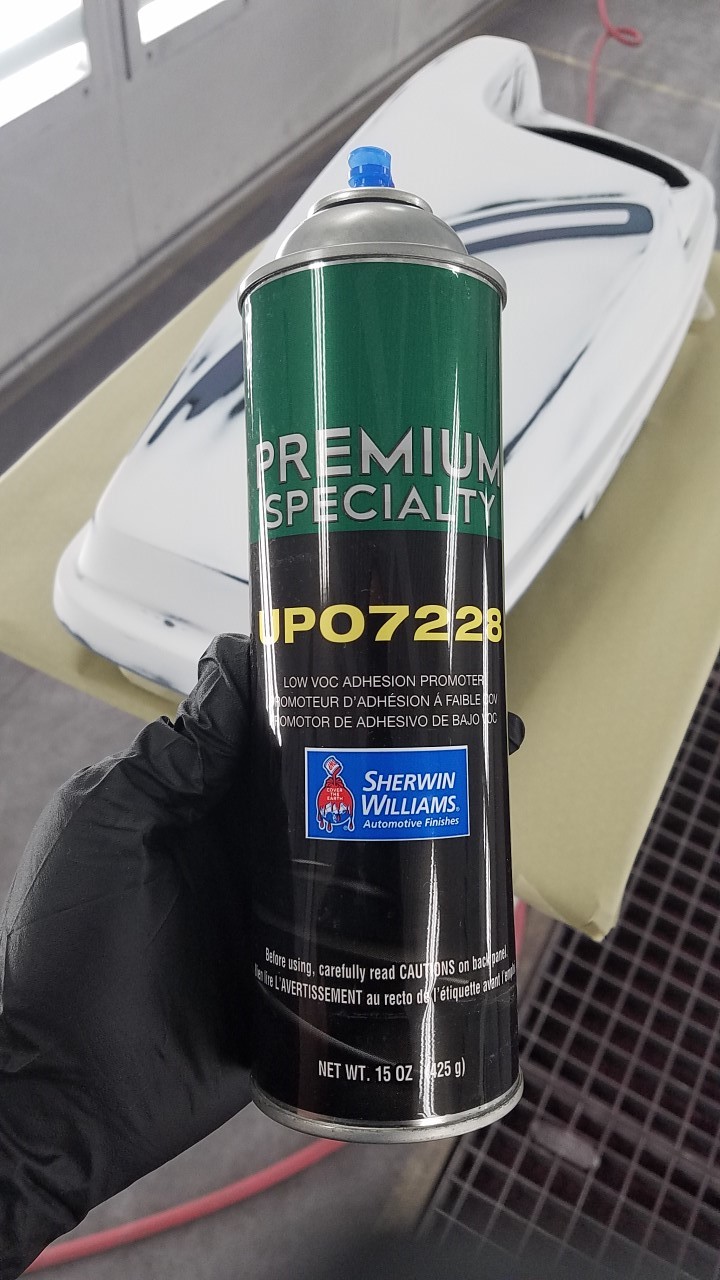

Note: Skipping this step will cause failure to your paint process.

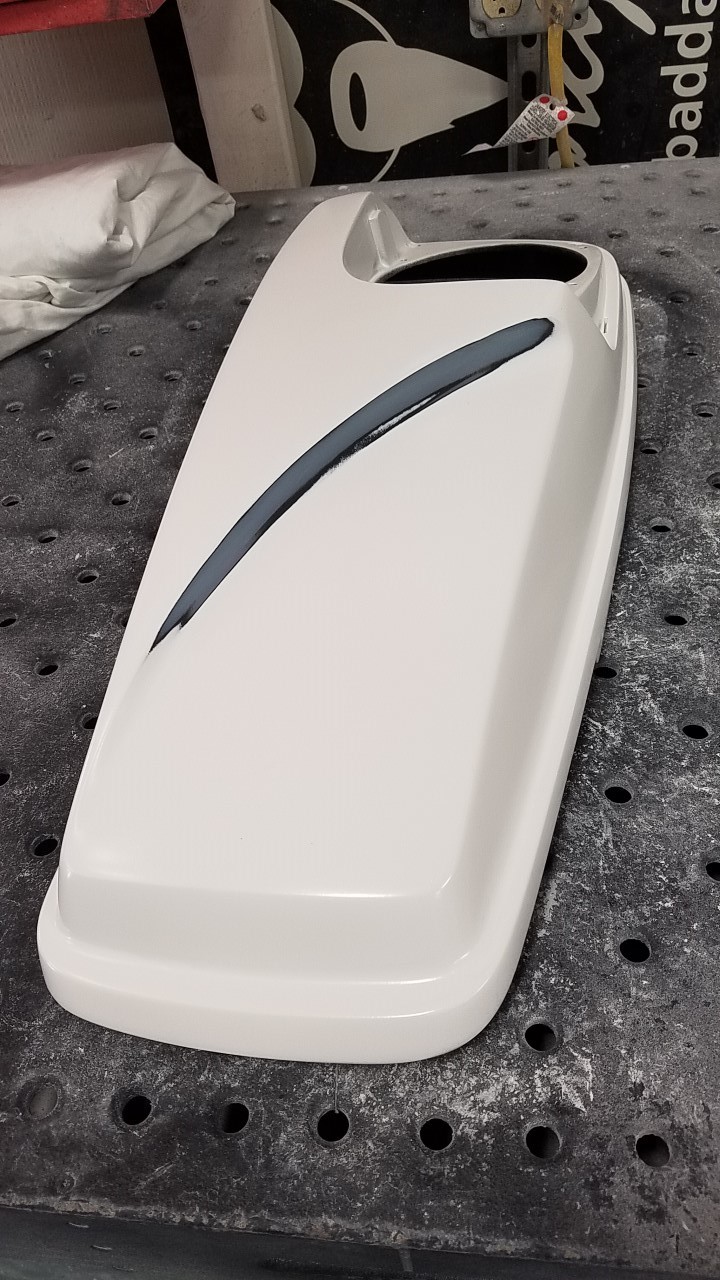

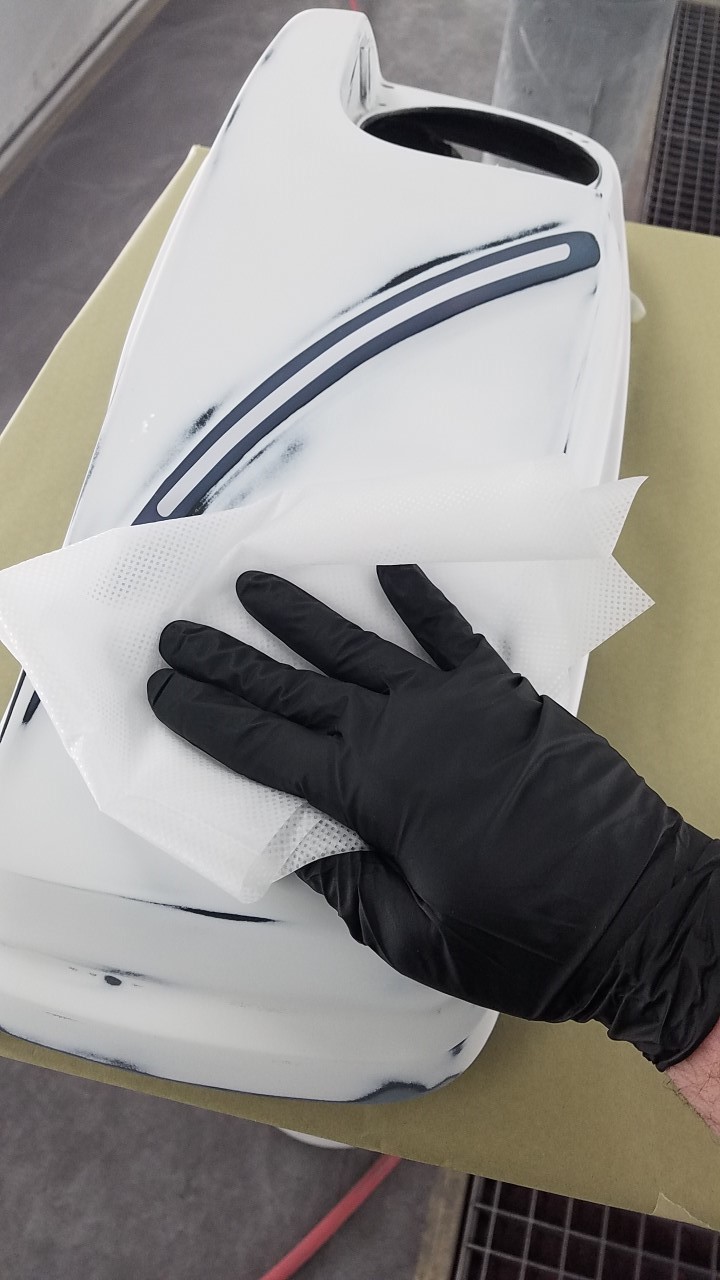

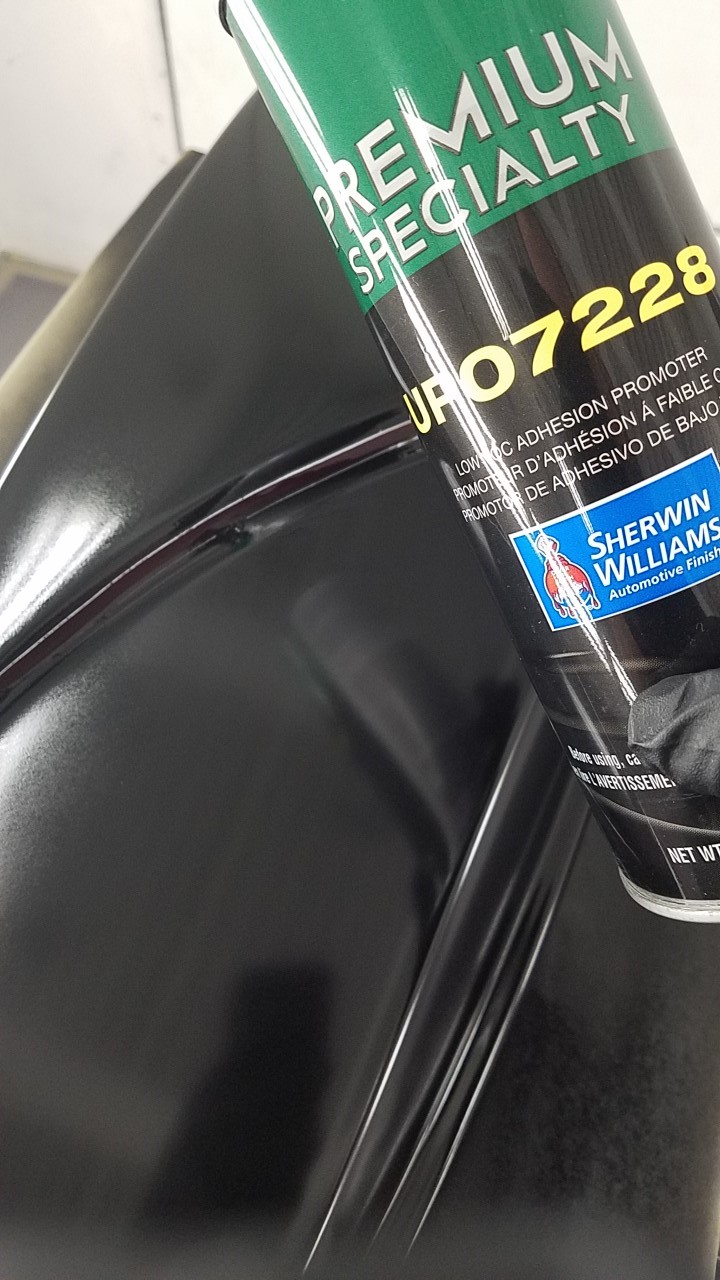

We recommend starting with a black sealer or base to cover up any unmasked area to prevent light from bleeding through the paint. After the sealer flashes, apply your base coat, then mid-coat (if applicable).

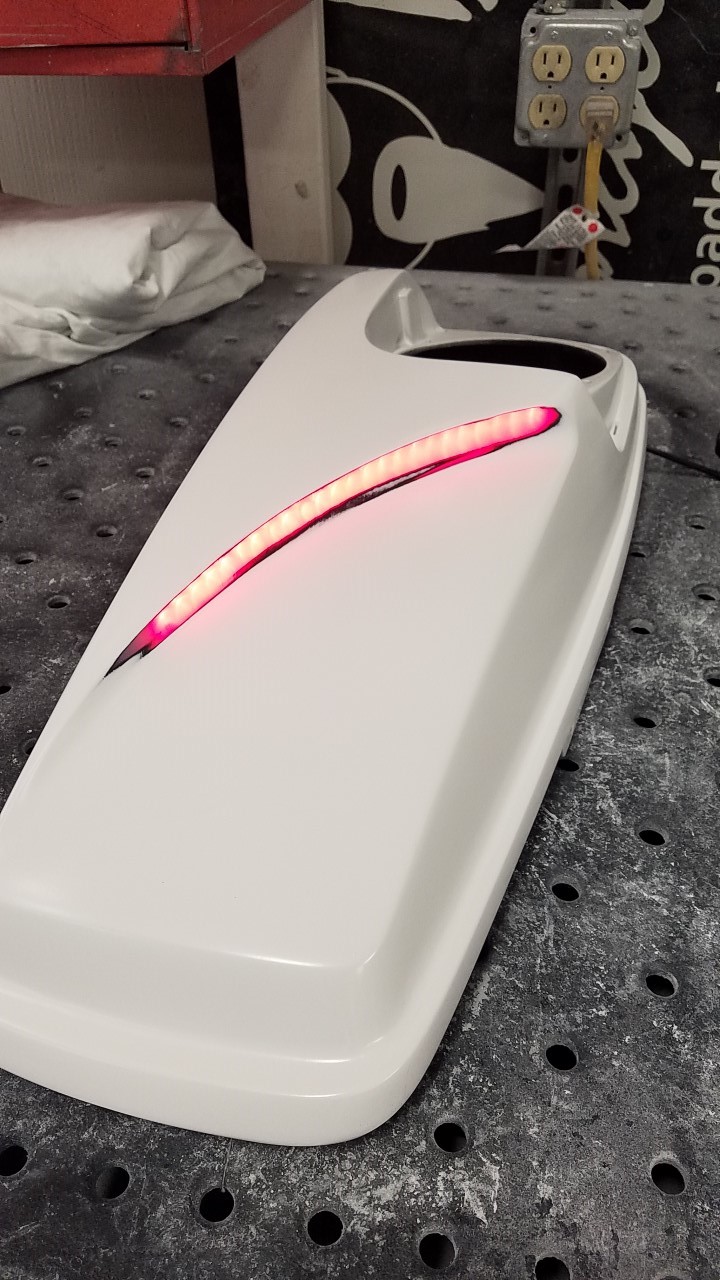

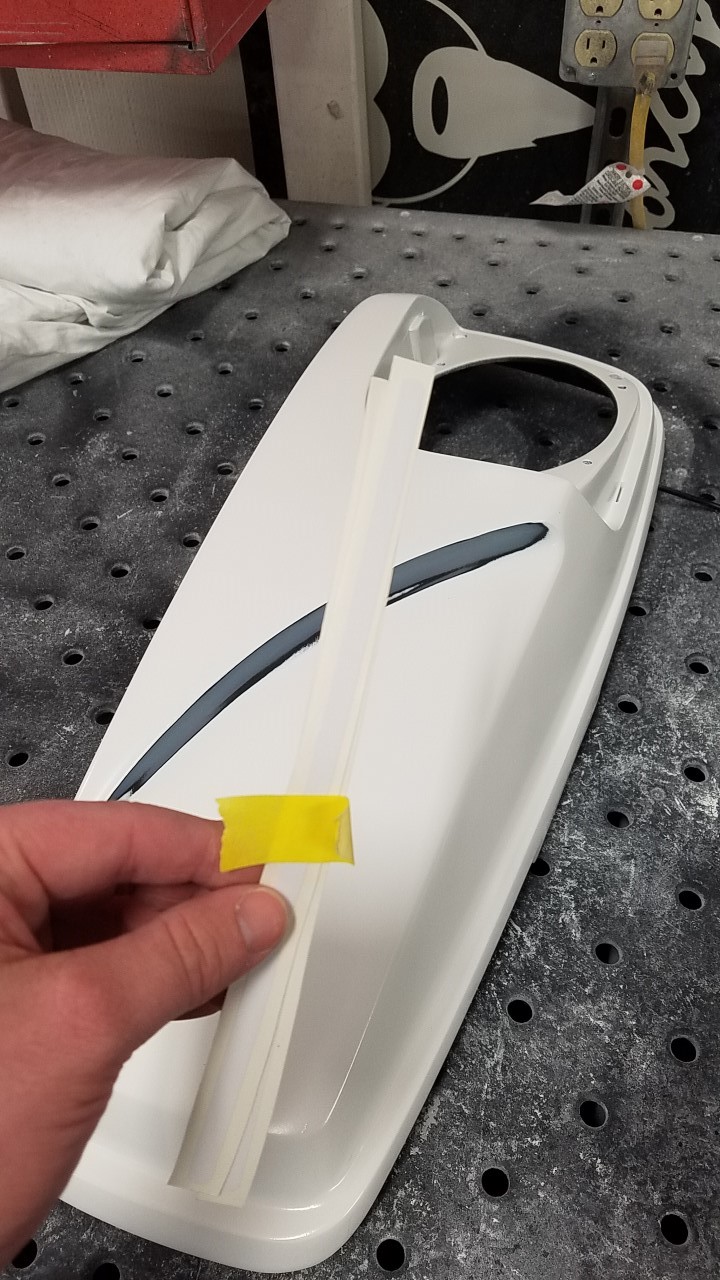

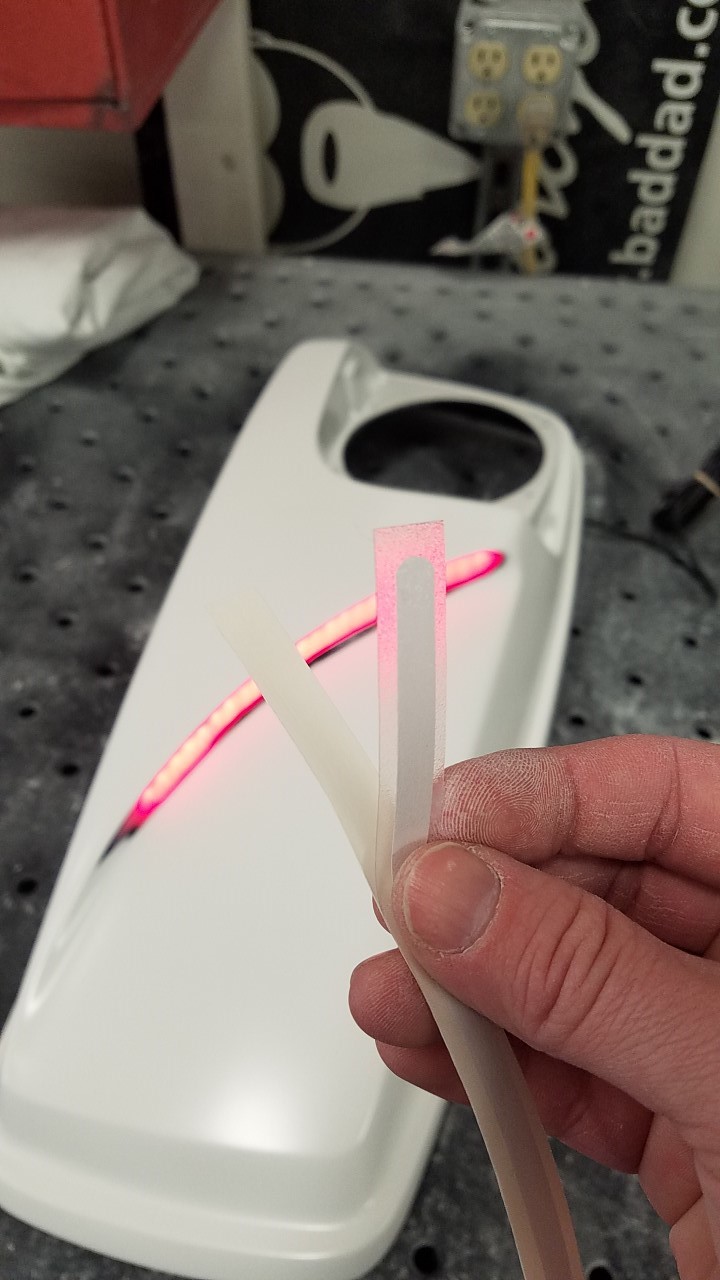

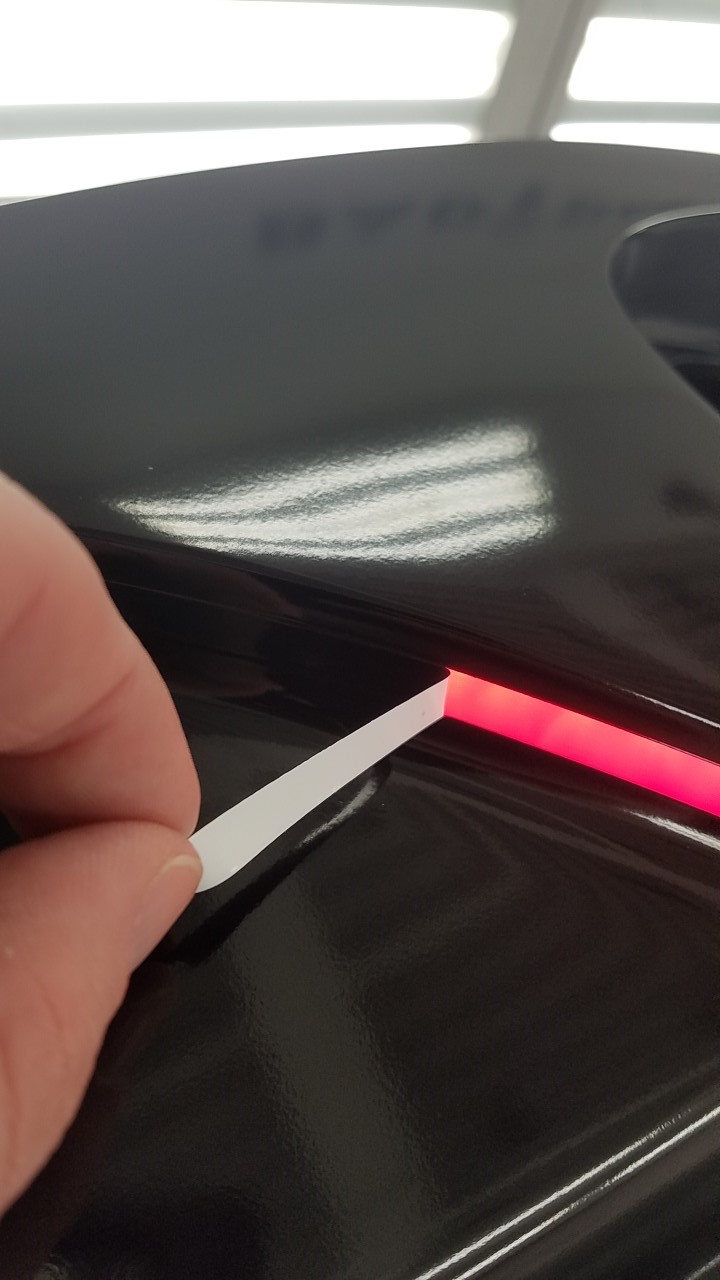

If no light bleeds through, you can peel out your masking material. This leaves behind the exposed lens material and the light is able to shine through the lens in the lid.

Finish by using your paint manufacturer's recommended clear coat over the entire lid, including the lens & LED area. This will also seal your paint edge and protect your lens. Not clearing over the lens may result in failure, cracking, and/or discoloration of the lens.